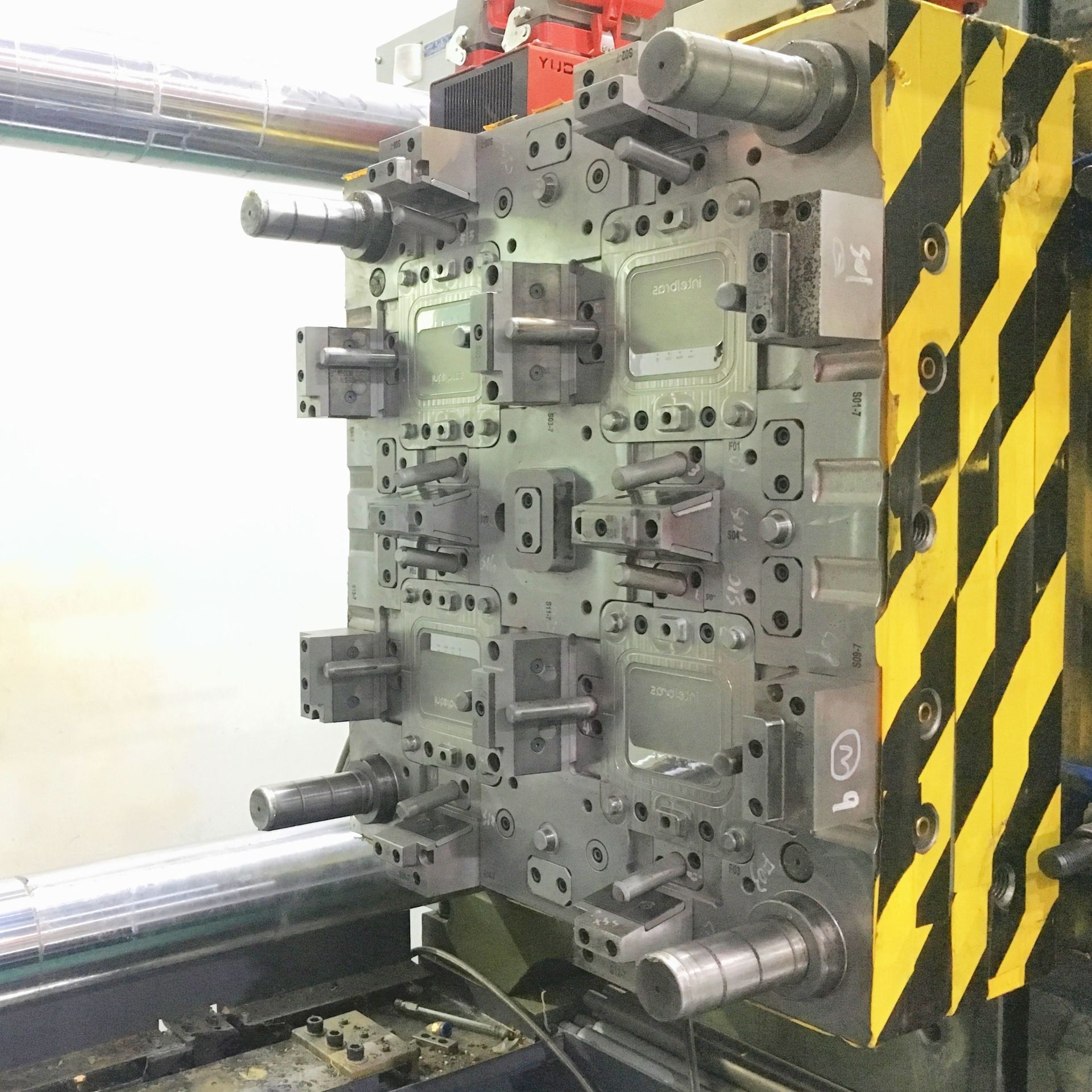

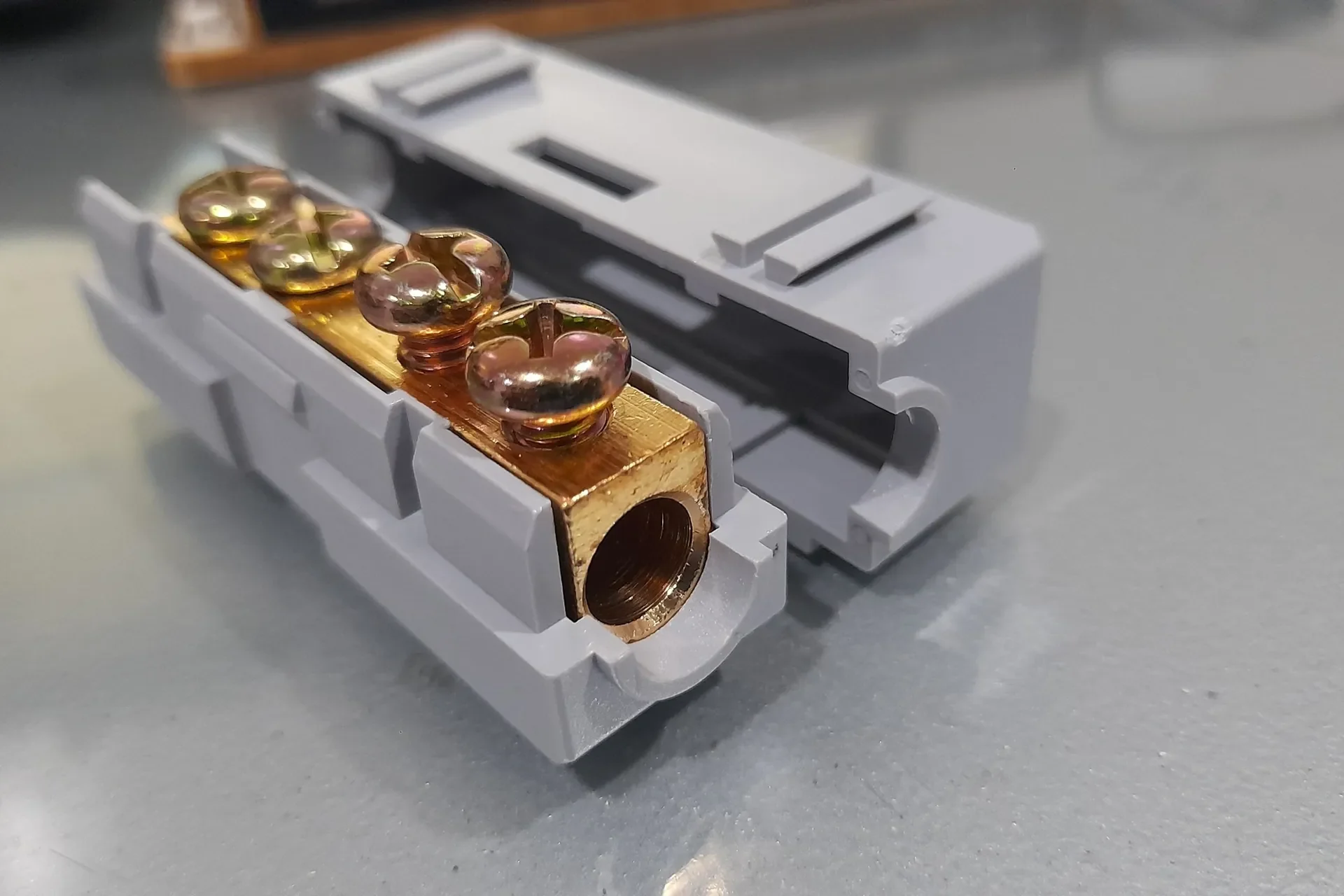

We’ve been making molds for plastic for over thirty years, implementing hundreds of projects in a wide variety of sectors. Our team includes highly experienced professionals and young technicians to whom we share our skills and our passion for our work.

Do you want to quickly find out the price of your product, including all costs? This is also a good way to proceed! We’ll get back to you promptly!

Our designers have extensive experience in the design of plastic articles and their industrialization.

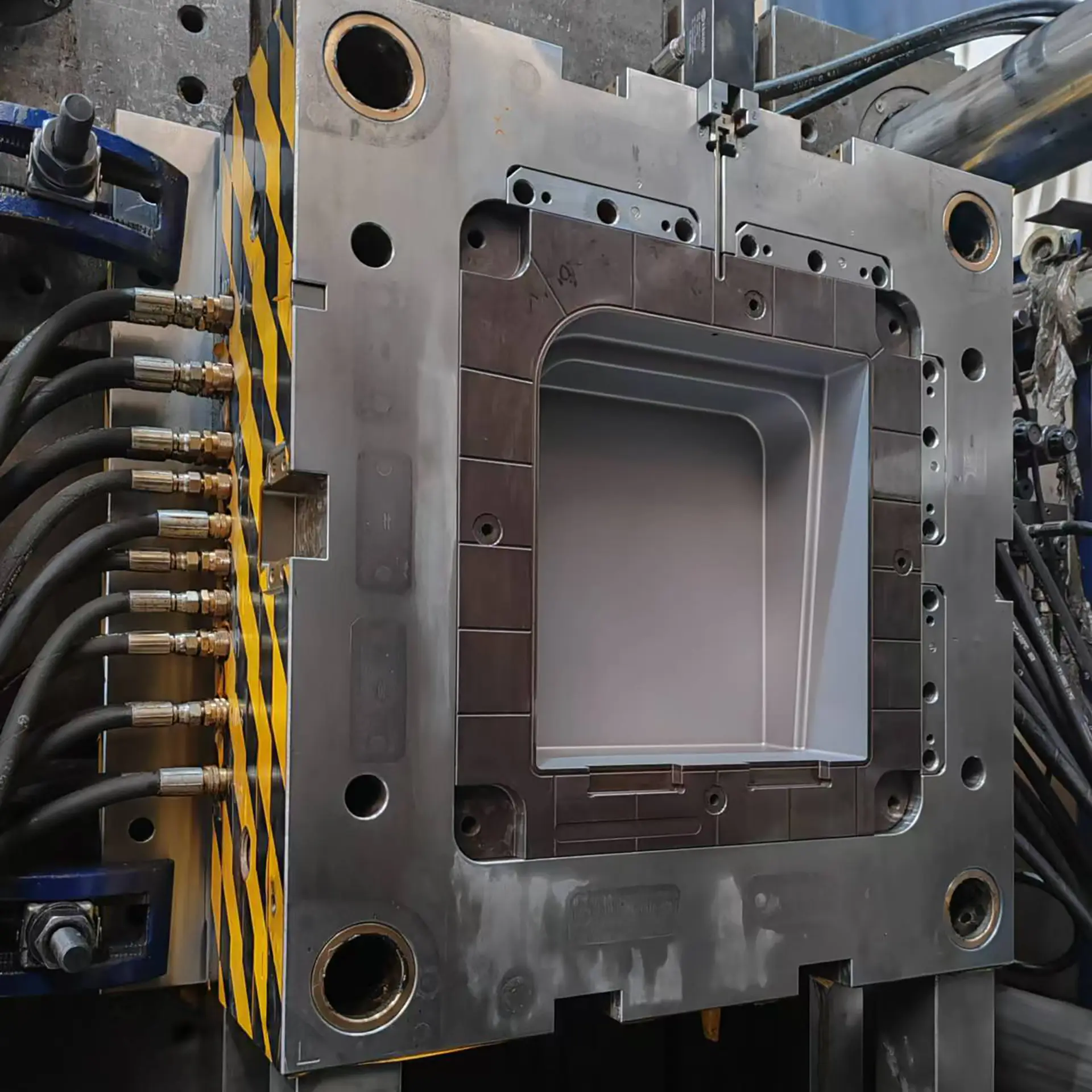

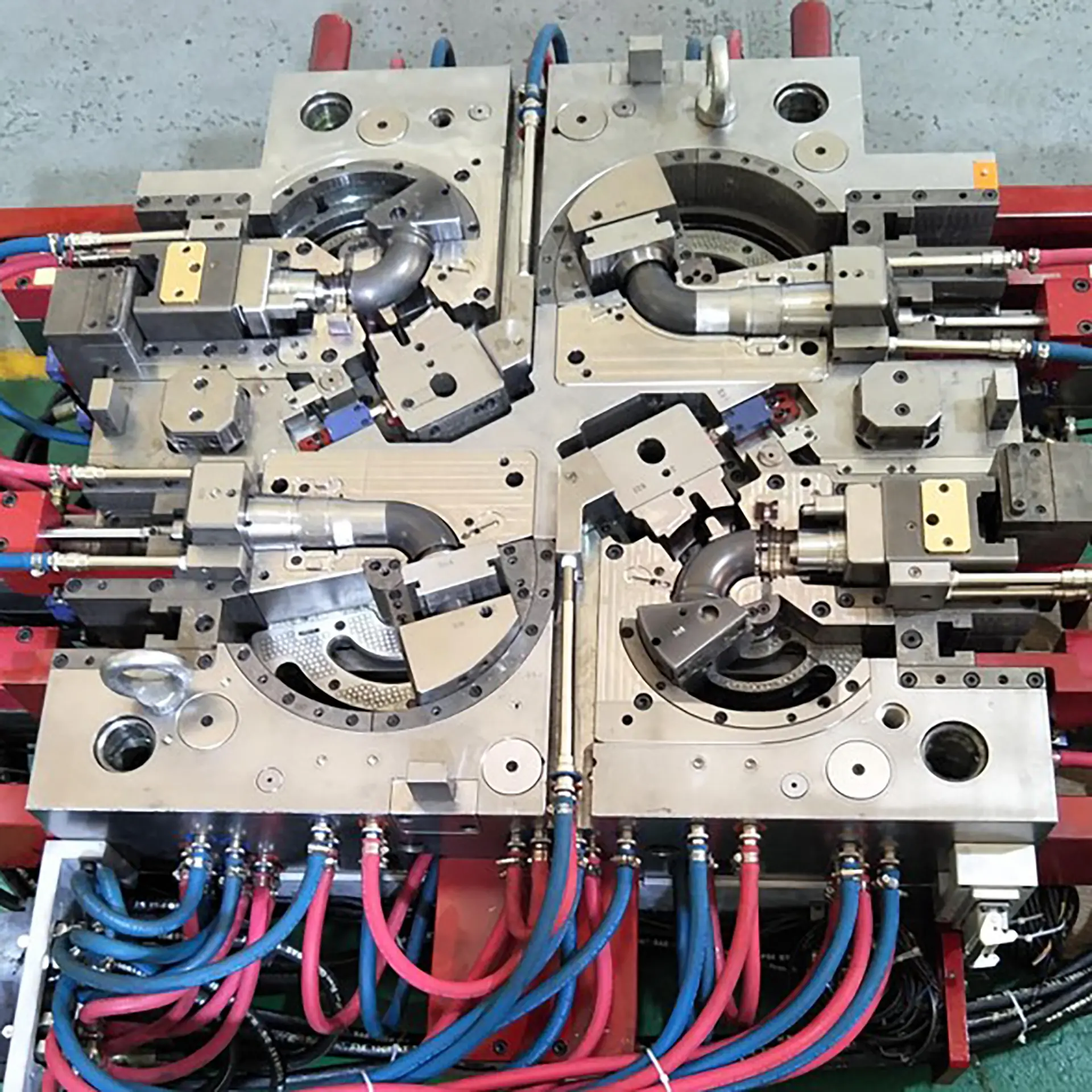

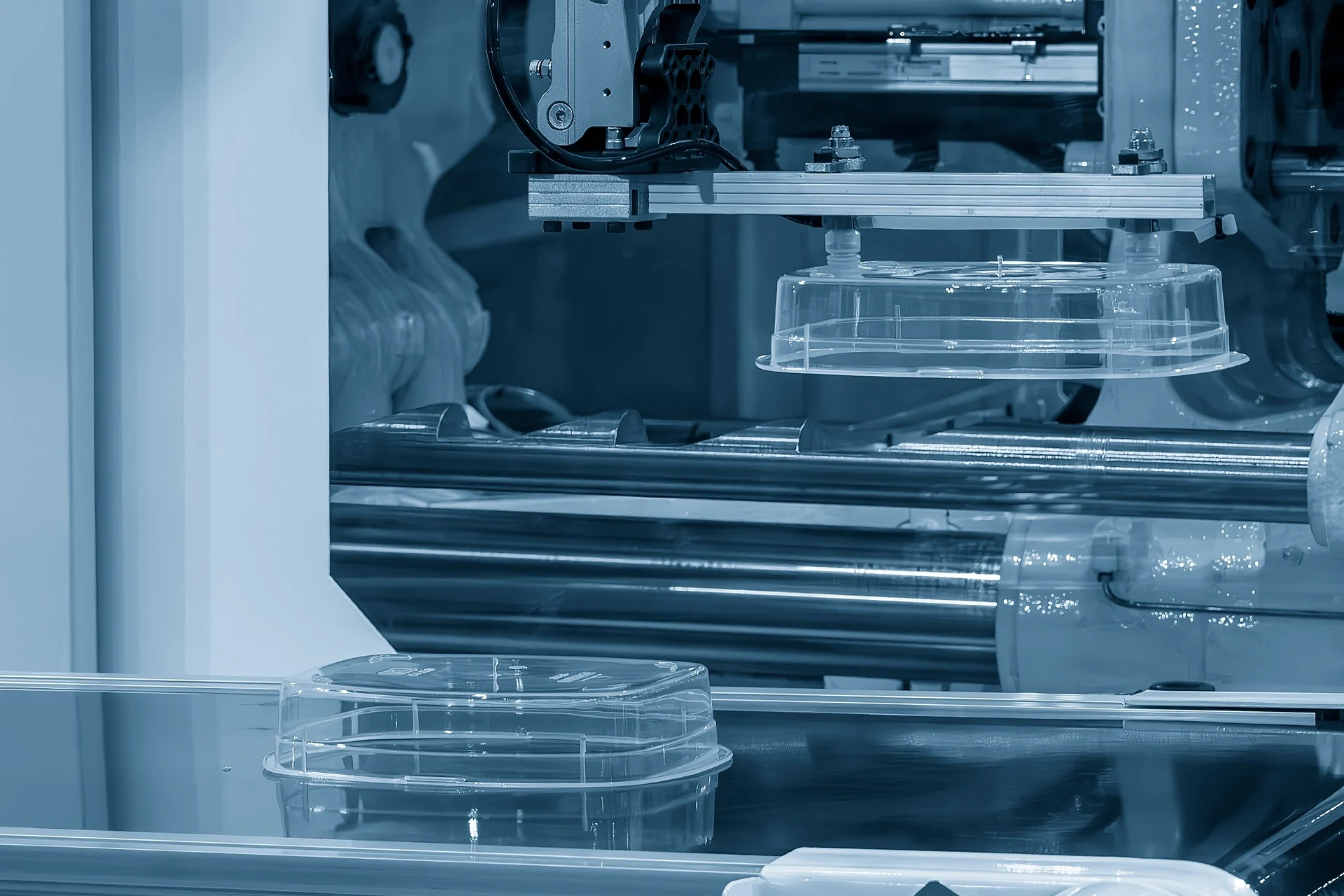

Most of the products we receive are injection molded, but we also offer other technologies (compression molding, liquid silicone, etc.)….

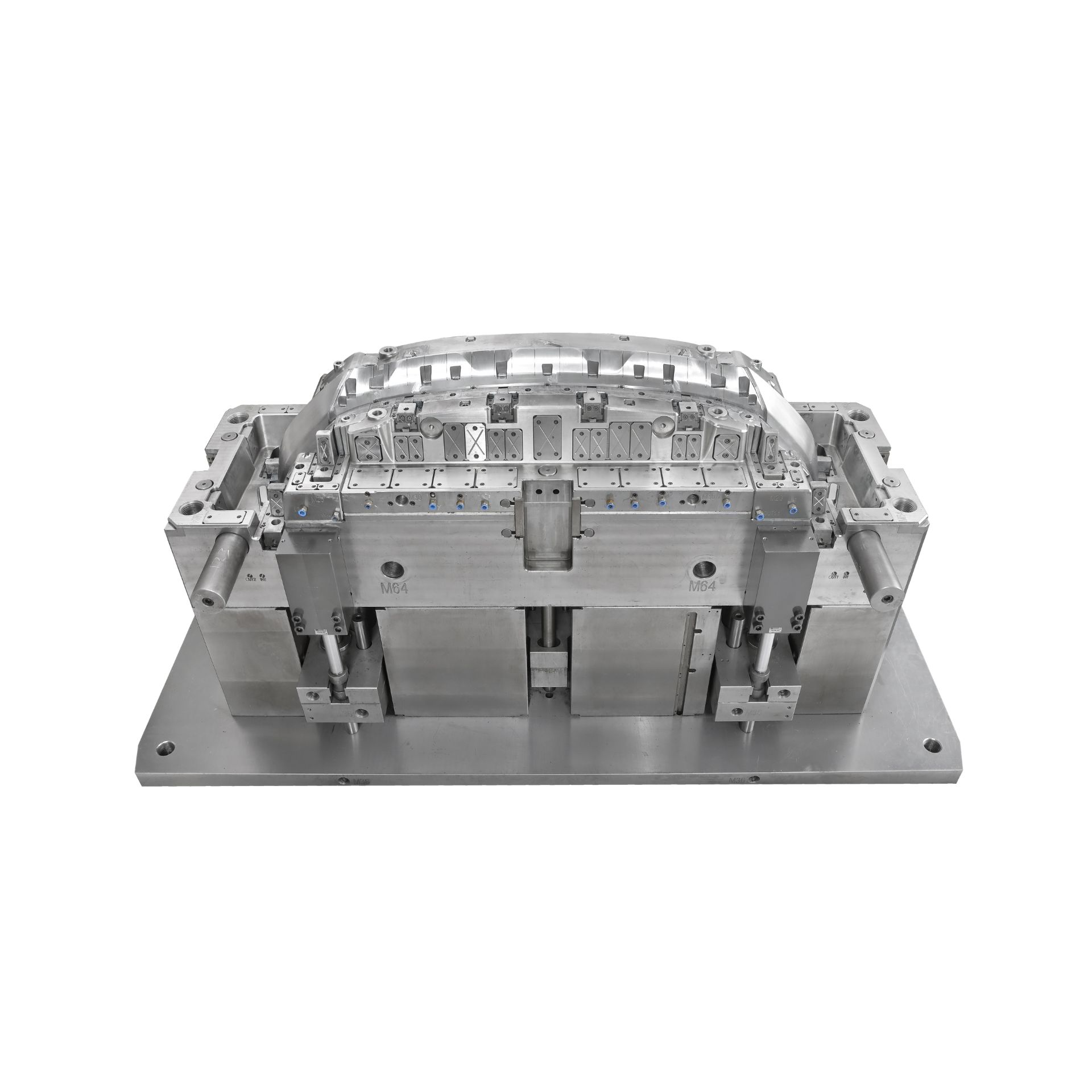

We offer a comprehensive service in the design and production of injection molds, with extensive experience, competitive costs, and rapid solutions. We carefully analyze technical requirements, supply the finished product, guarantee support, certified quality, and maximum project confidentiality.